How Are RC Car Aluminum Upgrades Made?

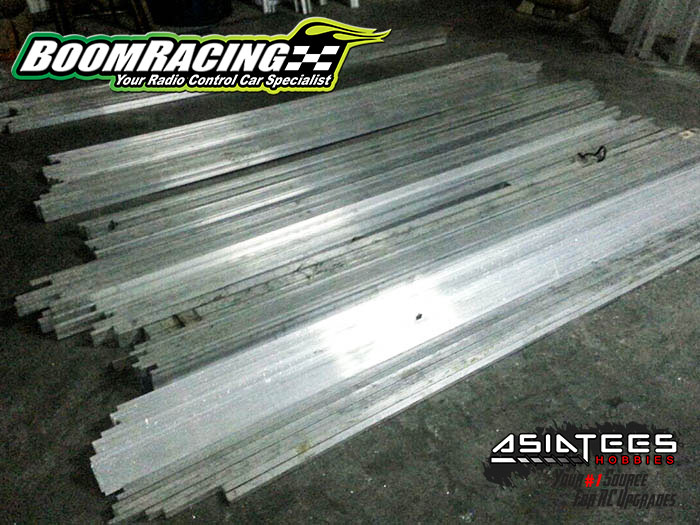

As the name implies, the raw material we need is aluminum. For different parts, we can get different shapes of aluminum. For example, we can get an aluminum cube for parts like gear box and get an aluminum stick for parts like steering linkage.

Then we need the magic CNC machine. CNC stands for computer numerical control, in which computers play an integral part of the control. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine via a post processor, and then loaded into the CNC machines for production. Since any particular component might require the use of a number of different tools - drills, saws, etc., modern machines often combine multiple tools into a single "cell". In other installations, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD design.

When we took the part out of the CNC machine, usually it has a lampstand under it. We use another machine to cut it off and then it has the exact shape we need now. The last step before we can put it on our cars is anodizing. No part is shinny metallic color before this step. It also adds a protective anodic films to prevent wearing out easily. When this step finished, it's time to try them out and see how strong and flexible they are when compared with the plastic parts.